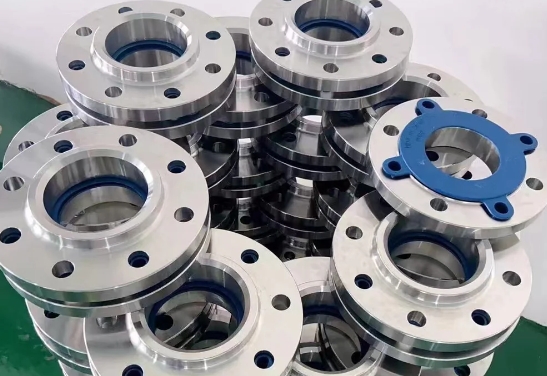

Stainless steel flange is made of stainless steel material, which can meet the performance of withstand strong pressure and tensile, stainless steel material as one of the highest strength materials in building metal materials, parts processing is easy to use, and can meet the requirements of architects and structural designers

The metal material produces a chemical reaction with oxygen in the atmosphere, the surface will form a layer of oxide film, generally formed by carbon steel iron oxide, iron oxide continues to oxidize, resulting in the occurrence of voids, stainless steel flange has anti-corrosion, to prevent rust, wear resistance and other advantages, widely used or many

Problems and methods of stainless steel flange

When welding stainless steel flanges, it is required to set the corrosion of the flange cover, and the current is small at the time of welding, and it is required to ensure that it can be cooled quickly

When making stainless steel flanges, the first thing that should be used is to increase the appropriate stability factor in the stainless steel flanges, such elements can be fixed to a certain extent, and there will be many problems when welding stainless steel flanges.

For example, repeated heating will reduce corrosion to some extent. This situation needs attention, otherwise it will seriously affect the quality of the project.

The solution to the stainless steel flange method is to replace the parts or replace the flange, which can not be solved at the construction site, and the polymer composite material is suitable for on-site sealing, which is a method

Especially in the flammable and explosive situation, show its advantages, safety and simple, low cost, for the enterprise to solve most of the flange leakage problem, eliminate security risks, for the enterprise to save more maintenance costs.

The above is a description of the advantages of stainless steel flanges and the leakage problem of stainless steel flanges. If you want to know more, please pay attention to the website