The general key role of stainless steel flanges in the use of pipelines is to connect, which is often used in various pipelines, especially large and medium-sized long-distance metal material transportation pipelines, so as to choose flanges for long-term application of pipelines

The stainless steel flange is at the junction of the pipe, the application of the flange as the socket of each section, rather than using the method of immediately connecting the pipe, which is more reliable, the socket is also stronger, therefore, most of the transportation pipes are used stainless steel flanges, so what do you need to do before welding? Let’s take a look

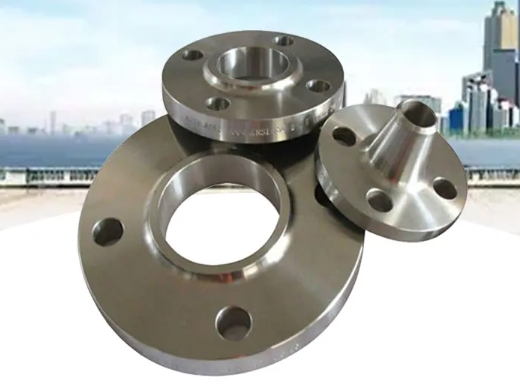

Stainless steel flange knowledge

Stainless steel flanges are widely used in the petroleum industry, water and natural gas pipelines, most of which are under corresponding pressure. This kind of thin bellows is generally welded process, because it is too thin, about 0.2 mm, difficult to weld process.

The welding process includes welding, brazing, etc. The arc welding process of 304 stainless steel flanges or other pipelines means that the arc can not directly point to the bellows, but is arc hot melt welding on the bellows.

Stainless steel flange before welding what to prepare

Remove oil and other dirt from stainless steel corrugated flange. Assuming the welding process flange and leakage, the original welding process scars should be eliminated, the straight pipe of the flange should be polished and polished metal luster, the straight pipe of the bellows is too thin and can not be polished, ground and cleaned, and the light should be polished and polished with a manual emery cloth.

Welding process assembly, fusion treatment implementation can be stacked on the flange pipe straight pipe surfacing layer, production is 0~0.05 mm open space or manual grinding.

Arc forward in the flange tube is essential. The arc refers to a very thick pipeline, the arc flame is used to heat the bellows, the edge of the bellows is blocked with welding wire, and the stainless steel welding wire is dissolved.

Should be welded process thick wall pipe, select short welding or spot welding. In the welding process, the melting standard of the bellows should be consulted at any time, under normal circumstances, 1 time should be melted 1 or 3 molten pools, so it is not suitable for 1 time to 1 welding process. Especially in the case of large open space, it is very easy to burn through.