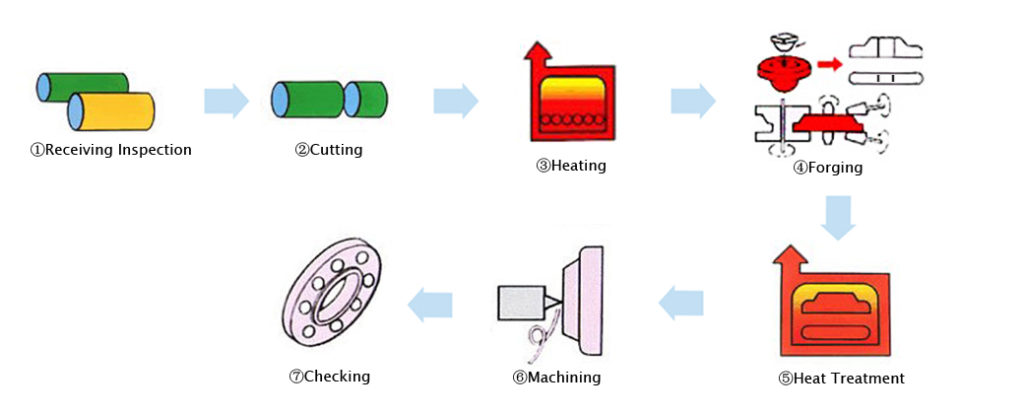

Flange flow chart

①Receiving inspection of raw material. It is the first compulsory chain to guarantee good quality. The testing items refer to chemical composition, mechanical capacity and metallographic analysis.

② Cutting raw material. Correctly and strictly controlling cutting size and proportion can ensure moderate cost.

③ Heating. It is a very important step for flange quality. It is the necessary to record the heating temperature in details to avoid overheating. Overheating will destroy the structure of the metal and mechanical properties.

④ Forging. Forging process is divided into free forging and die forging. The forging time and strength of flange is different for different pressure class.

⑤ Heat treatment. The purpose of heat treatment is to eliminate the stress inside of flange so that the density is more evenly. Carefully recording the temperature of heat treatment and cooling time are the keys.

⑥ Forging blank inspection. Choosing some blank samples to test the chemical composition and mechanical property again to ensure all items are qualified.

⑦ Machining. In the machining process, the inspection is carried out along with the processing, so that to guarantee each part of flange is qualified.

⑧ Finishing checking. Finished products will be checked 100% before delivery to ensure the cargos are perfect.

The whole production chains are all very important, so the datas of each production step of flange must be recorded in details according to ISO request. It is the guarantee for good quality.