One Italian customer placed two orders about Slip on flange and test flange to Metleader recently. It is the first time Metleader’s flanges are exported to Italy. The are customized orders according to drawings, the quality requested very strictly.

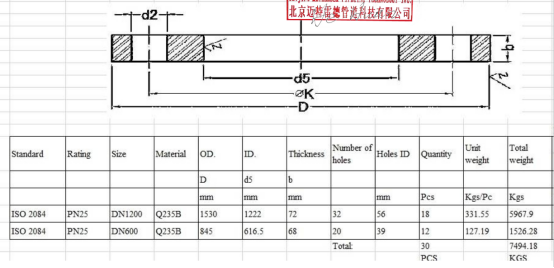

Slip on flange order

Slip-on flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. The standards frequently followed as below:

ASME/ANSI B16.5 Class 150 SO/Class 300/Class 600/Class 900

BS 3293 Class 150 SO/Class 300/Class 600

DIN 86029 PN 10

Material of sliding (Slip on) flange:

The stock of slip pipe flanges includes AWWA, ANSI, pressure vessel, and slip pipe flanges matching ASME flange diameters and boreholes.

Carbon Steel: A105, A350 LF2

Stainless steel: A182 F304 F304L/F316 / F316L/F321

Alloy steel: F11, F12

Advantages of sliding (slip on) flange:

Low-cost installation

Less time is required to ensure the accuracy of pipe cutting

They’re easier to align

Because the pipe slides into the flange before welding, the hub of the sliding flange is lower

Flanges are welded inside and out to provide sufficient strength

They can prevent leaks

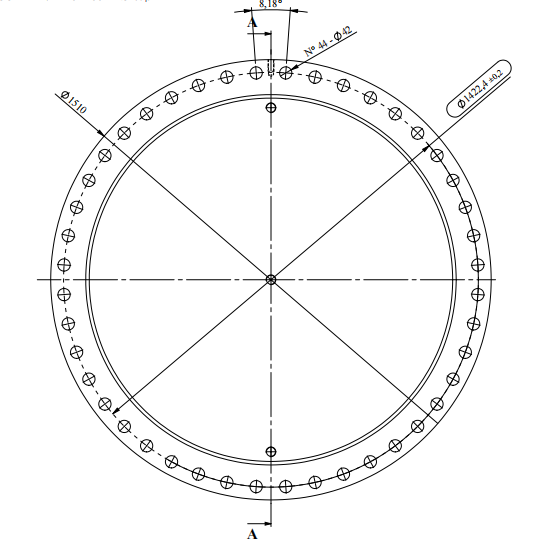

Test flange (Blind flange) order

Blind flange is a kind of circular plate, which has all relevant holes, but no central hole. Due to this characteristic, this flange is used to close the end of the piping system and the opening of the pressure vessel. Once the pipeline is closed and must be reopened, it can easily enter the interior of the pipeline or vessel.

Blind flanges are used for closed ends of piping systems. It is a circular plate without central support, but with all suitable bolt holes. This blind flange is available in various sizes and materials to provide positive closure at the end of pipes, valves or equipment nozzles. Once the pipe is sealed, this flange facilitates easy access to the pipe. Blind flanges are sometimes customized or machined to accept nominal size pipes and bend them.