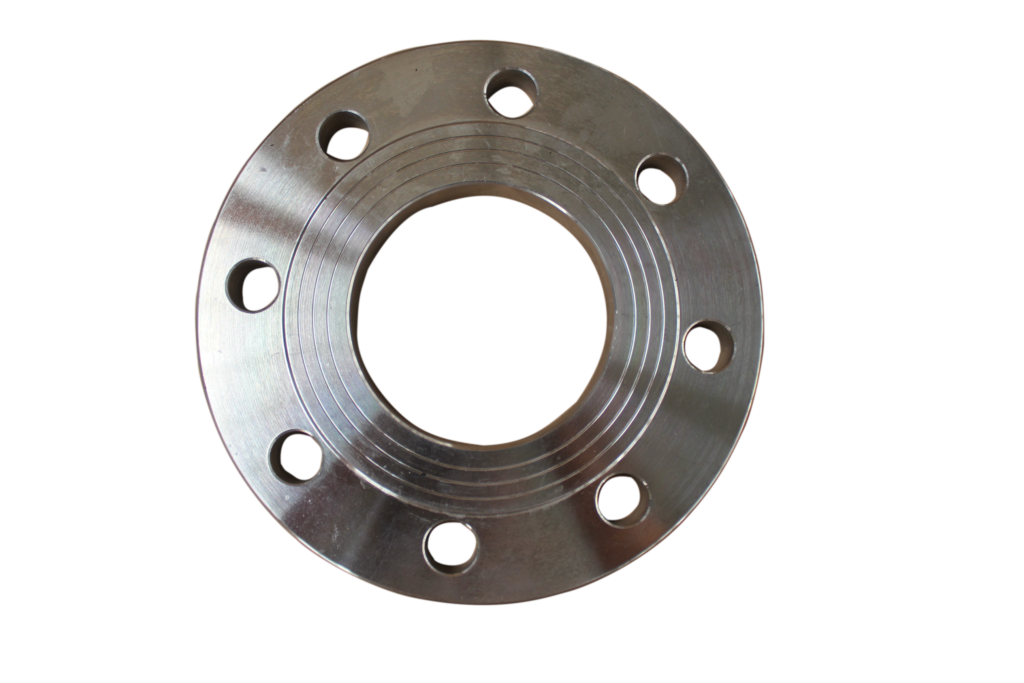

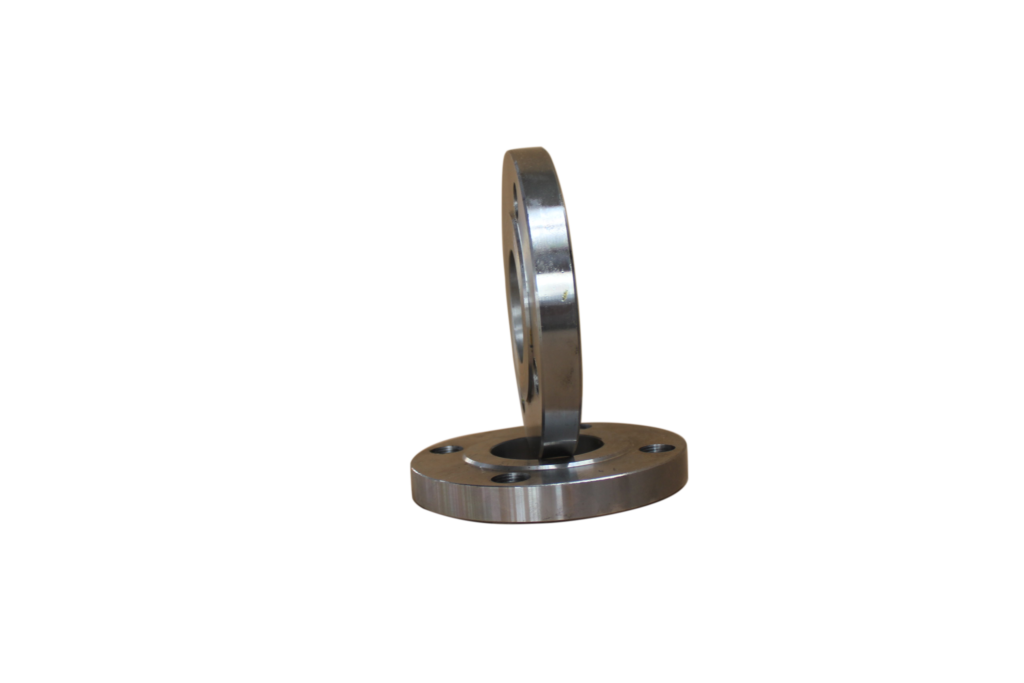

Carbon steel butt welding flange is not easy deformation, good sealing, widely used for in pipeline pressure or temperature fluctuations in the pipeline or high temperature, high pressure and low temperature, the advantage of cheaper prices and heat-resistant performance good we all know when working temperature of 75 degrees, the softening temperature of 135 degrees.

Carbon steel exhibits high tensile strength, making butt welding flanges reliable for handling significant pressure and stress within piping systems.

The robust nature of carbon steel enhances the longevity of butt welding flanges, allowing them to withstand harsh environmental conditions and demanding operational requirements.

Carbon steel is generally more cost-effective compared to some other alloys, making carbon steel butt welding flanges a budget-friendly choice for many applications.

Carbon steel has excellent weldability, allowing for efficient and reliable welding processes during the manufacturing of butt welding flanges.

The ease with which carbon steel can be welded makes it a preferred choice for various welding methods, ensuring secure and leak-free connections in piping systems.

While not as corrosion-resistant as stainless steel, carbon steel forms a protective oxide layer when exposed to the atmosphere, providing a degree of resistance against corrosion.

Additional protective coatings or treatments can be applied to enhance corrosion resistance, depending on the specific requirements of the application and environment.

In summary, the four key characteristics of carbon steel butt welding flanges — strength and durability, cost-effectiveness, to their popularity in industries such as construction, oil and gas, petrochemical, and others where reliable and cost-efficient piping solutions are essential.

It’s important to consider the specific requirements of each application and the environmental conditions to ensure the optimal performance of carbon steel butt welding flanges.