Treatment of stainless steel flange surface process

Treatment of stainless steel flange surface process

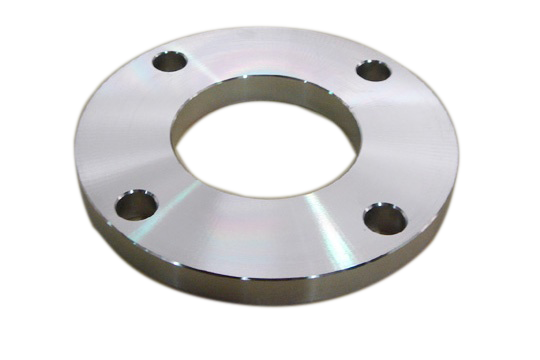

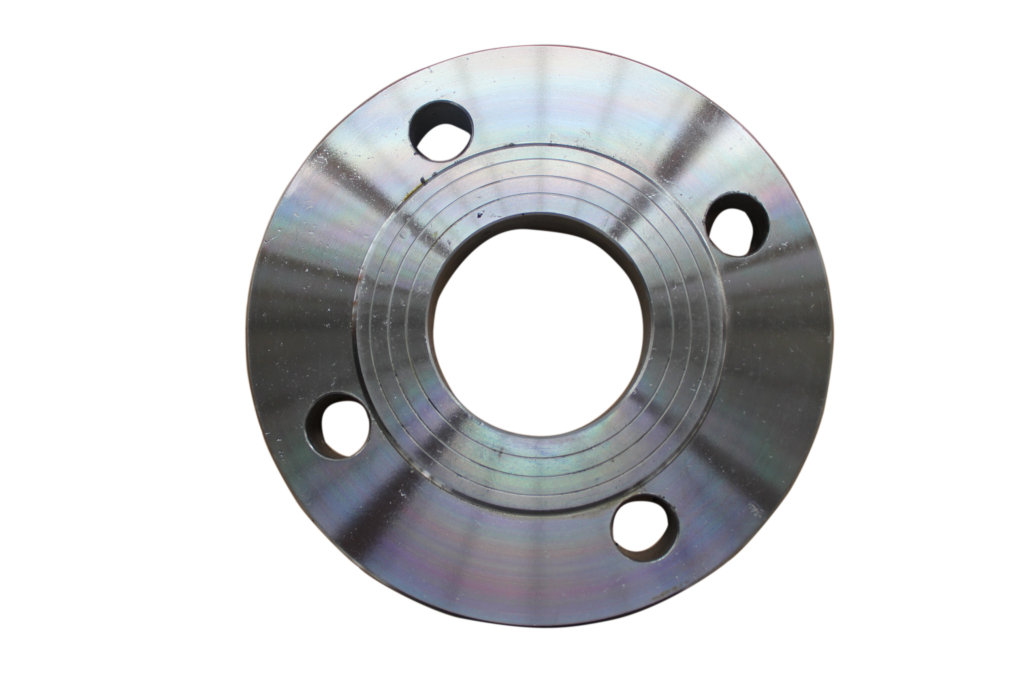

Flange surface is smooth and decided the sealing surface of the connection effect, in the usual contact will have many such rough stainless steel flange, it is difficult to seal

so the roughness of the stainless steel flange for sealing effect is very important, here and share with you why roughness determine the connection quality of the stainless steel flange.

Use a grinding wheel or abrasive belt to remove rough spots and uneven surfaces.Follow up with progressively finer abrasives to achieve a smoother finish.

Turning stainless steel flange surface knife grain, for example, is the spiral line and using the metal gasket,if the roughness value larger pads can not blocked knife grain The spiral groove is formed under the pressure of the medium, the medium can be leaked out of the groove.

Soft sealing gasket on the surface of the stainless steel flange to the extent Demand much lower. This is because it is easy to deform, can block the cutter profile so as to prevent leakage.

On the soft gasket, stainless steel flange and too smoothAdverse, because at this time the resistance to the leakage of the interface becomes smaller.

So, if the stainless steel flange surface roughness is larger, we can use some soft gasket, in conjunction with the flange bolts to ensure that the stainless steel flange of the seal, as to how to choose in concrete flange gasket. This is usually the accumulation of experience.

Consider outsourcing the task to a professional metal finishing or polishing service if the flange requires a high-quality, precision finish.

Remember to follow safety guidelines, especially when working with abrasive materials or chemicals. Additionally, it’s essential to consider the intended use of the flange and any industry-specific requirements for surface finish and cleanliness.

Use of stainless steel flange

Stainless steel flanges serve a critical role in various industrial applications, providing a durable and corrosion-resistant connection point between pipes, valves, and other components in a piping system.

The inherent properties of stainless steel, such as its resistance to rust and corrosion, make flanges made from this material ideal for applications where exposure to harsh environments, chemicals, or extreme temperatures is common.

Industries such as petrochemical, oil and gas, chemical processing, and food processing often rely on stainless steel flanges to ensure the integrity and longevity of their piping systems.

Moreover, stainless steel flanges contribute to the overall safety and reliability of the interconnected components.

Their robust construction and ability to withstand challenging conditions make them suitable for high-pressure and high-temperature environments.