Petrochemical plants, intricate ecosystems of high-pressure and corrosive environments, demand materials and components that can withstand the challenges inherent in processing and transporting volatile hydrocarbons. Stainless steel flanges emerge as indispensable elements within these plants, providing critical connections and terminations that contribute to the overall integrity and reliability of the intricate piping systems. This article elucidates the nuanced role of stainless steel flanges in petrochemical applications, emphasizing their advantages and specific applications within this demanding industrial sector.

1. Corrosion Resistance in Aggressive Environments: Petrochemical processes expose equipment and piping systems to a myriad of corrosive substances, ranging from acids to caustic solutions. Stainless steel flanges, with their exceptional corrosion resistance, act as frontline defenders against the corrosive effects of these substances, ensuring the longevity and reliability of critical connections in the petrochemical infrastructure.

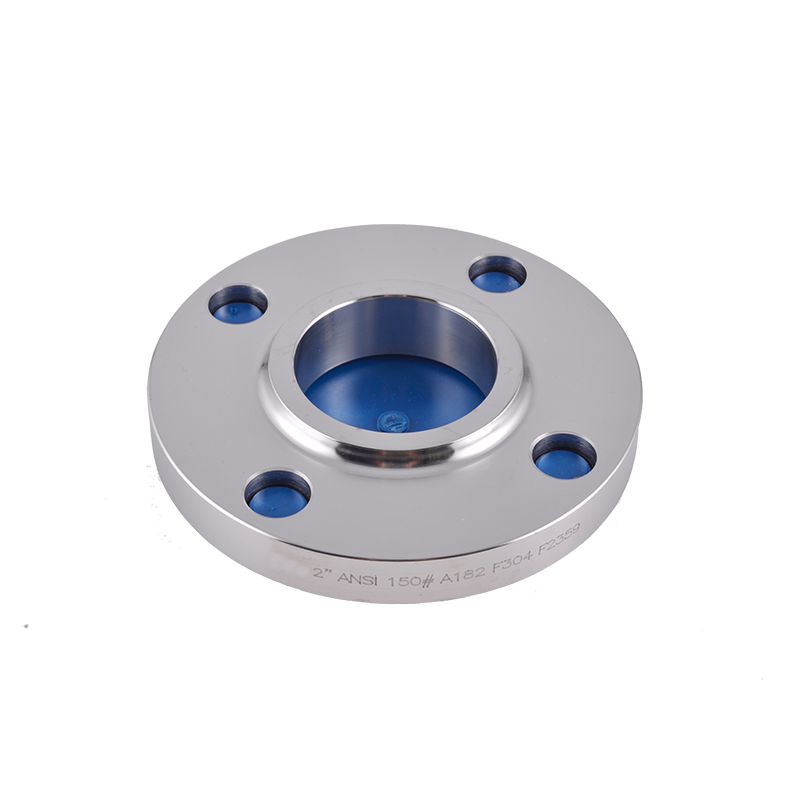

2. High Mechanical Strength in High-Pressure Systems: Petrochemical operations often involve high-pressure processes, necessitating materials with superior mechanical strength. Stainless steel flanges, especially weld neck and slip-on types, excel in these applications, providing robust connections that can withstand the extreme pressures associated with processes such as distillation, cracking, and fractionation.

3. Resistance to Extreme Temperatures: The versatility of stainless steel flanges is highlighted in petrochemical plants where temperature differentials are common. These flanges maintain their structural integrity across a broad temperature range, ensuring reliability in applications where temperature fluctuations are inherent to the operational environment.

4. Facilitating Maintenance and Repairs: The design and characteristics of stainless steel flanges facilitate efficient maintenance and repair activities within petrochemical plants. Flanges such as spectacle blinds allow for temporary blockage or isolation of sections, enabling safe maintenance procedures without compromising the overall integrity of the system.

5. Contributing to Environmental and Regulatory Compliance: Stainless steel flanges contribute to environmental and regulatory compliance within the petrochemical sector. Their resistance to corrosion and leakage minimizes the risk of hazardous substance release, aligning with stringent industry standards and environmental regulations governing the safe operation of petrochemical facilities.

In conclusion, the utilization of stainless steel flanges in petrochemical plants is not merely a matter of material selection; it is a strategic decision driven by the imperative for durability, reliability, and safety in a challenging operational landscape. These flanges stand as sentinels, safeguarding the intricate networks that power the production of vital petrochemical products while concurrently meeting the rigorous demands of an industry that places a premium on performance, integrity, and regulatory adherence.