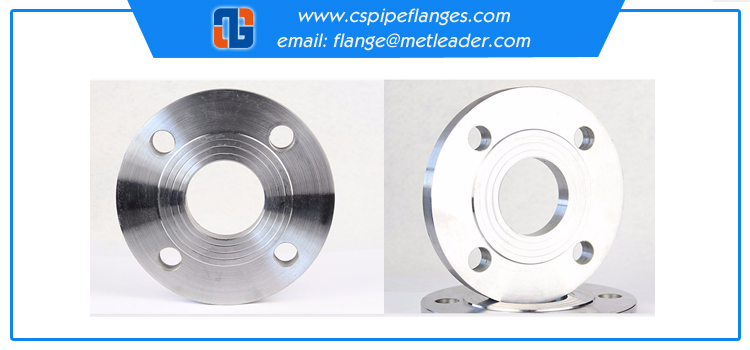

JIS Steel Flange

JIS Steel Flange Flat Welding Flange is a disk-like parts, in the pipeline engineering is the most common, flange is used in pairs, in the pipeline engineering, flat welding flange is mainly used for pipe connection, in the need to connect the pipeline on both sides of the installation of a flange, low pressure pipe can be used wire connection flange, 4 kg above the pressure of the use of welding flange, two pieces of flange with a gasket, and then fastened with bolts, different pressure flange has different thickness and the use of different bolts.

JIS Steel Flange Process Requirements

JIS Steel Flange Flat welding flange Forging process can be divided into forging, upsetting, extrusion, die forging, closed die forging, closed-type upsetting, closed die forging and closed upsetting because there is no flying edge, the material utilization rate is high, with a process or several processes may complete the complex forgings finishing, because there is no flying edge, The force area of the forgings will be reduced, the required load will also be reduced, however, should be careful not to make the blank completely limited, to strictly control the volume of the billet, control the relative position of the forging die and the measurement of forgings, and strive to reduce the wear of forged die, flat welding flange at low temperature forging, the size of the flange forgings produced by our company is very small, the forging with less than 700 ℃, and the surface no decarburization phenomenon.

JIS Steel Flange and Butt welds are welding methods for flanges and piping connections, flat welding flange welding only need a single side of the welding pipe and flange is not required to connect the inner mouth, welding flange welded installation needs flange double-sided welding, so the flat welding flange is generally used for low, medium pressure pipeline, butt welding flange for the high pressure pipe connection, the butt weld flange is generally at least PN2.5 PA, and the butt weld is used to reduce stress concentration.

![]()

JIS Flange Flat welding flange is divided into the following categories of main functions:

1. Pipeline failure, easy to disassemble detection

2. Connecting the pipe and keeping the pipeline good sealing performance

3. If a section of the pipeline problems, to facilitate the replacement of a section of the pipeline

JIS Steel Flange flat welding flange in the production and processing points:

1. The butt weld of the ring should be welded after welding, and make 100%-ray or ultrasonic flaw detection, and the radiographic inspection conforms to class II requirements, ultrasonic flaw detection conforms to Grade I requirement, the welding flange uses certain welding standard and the technical production processing, conforms to the national corresponding production standard and the request.

2. The production of flat welding flange plate should be ultrasonic flaw detection, no delamination defects, to ensure good quality and performance problems, according to a certain quality requirements of production and testing, to ensure the production and use of steel plate without quality problems.

3.It should be cut into strips along the rolling direction of steel, welded into a circular shape by bending, and the surface of the steel formed a ring of the cylinder, in the production of Hafaran should not be used in steel DINGXIANG flange plate directly machined into the neck flange, using a certain process production and processing.

![]()

Our company some type pipe flanges:

|

|

|

|

|

| Blind flange | Weld Neck Flange | Slip On Flange | Lap Joint Flange | Socket Weld Flange |

Some type steel flanges and different size:

carbon steel JIS flange

Stainless steel JIS flange

carbon steel JIS 10K flange

carbon steel JIS 5K flange