A slip-on flange is a type of flange that is slipped over the end of a pipe and then welded in place. It is one of the most common types of flanges used in piping systems. Slip-on flanges have a circular shape with a flat sealing face and bolt holes around the periphery.

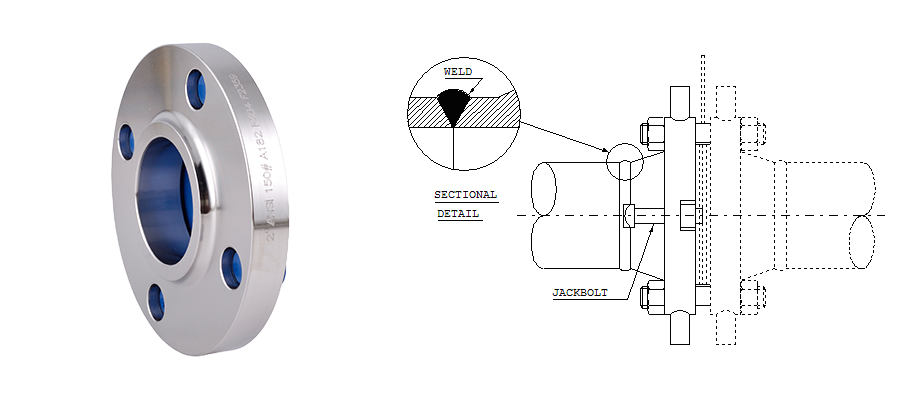

The slip-on flange is designed to slide onto the pipe, and once in position, it is welded to the pipe and the adjacent flange. The welding provides a strong and secure connection. The flange does not have a neck like weld neck flanges or a threaded connection like threaded flanges.

When using slip-on flanges, it’s important to ensure proper alignment and welding to create a secure and leak-free joint. The flange should be aligned with the pipe end, and the welds should be performed on both the inside and outside of the flange to provide a strong connection.

Slip-on flanges are designed to slide over the end of a pipe and are then welded in place. They have a slightly larger inner diameter than the outer diameter of the pipe to allow for easy installation. The fit between the slip-on flange and the pipe is typically not very tight or snug.

The slip-on flange is positioned on the pipe and then welded on both the inside and outside to secure it in place. The welds create a strong connection between the flange and the pipe, ensuring a reliable and leak-free joint.

It’s important to note that slip-on flanges are not designed for applications that require high-pressure or high-temperature conditions. They are typically used in low-pressure systems or where the piping system needs to be easily disassembled for maintenance or modifications.

If you need a tighter or more secure connection between the flange and the pipe, you may consider using other types of flanges, such as weld neck flanges or threaded flanges, which provide a more rigid and sealed joint. The selection of the flange type depends on the specific requirements of your application.