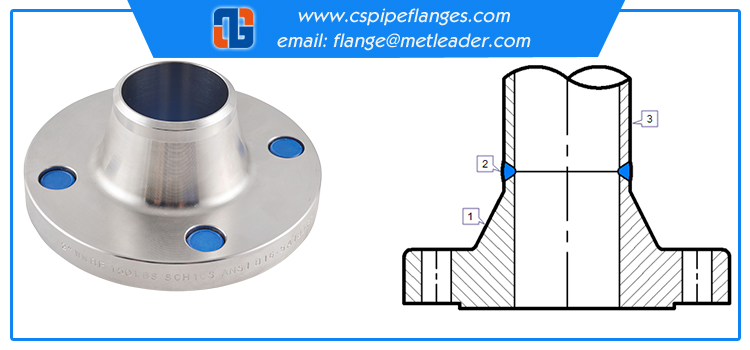

Carbon steel welding neck flange

Welding neck flange is a kind of pipe, refers to the neck and has a circular pipe transition and the pipe to weld the flange. Butt welding Flange is not easy to deformation, sealing good, widely used, has the corresponding rigidity and elasticity requirements and reasonable to weld thinning transition, welding distance from junctions, junctions from welding temperature deformation.

Advantages: The connection is not easy to deform, the sealing effect is good, the application is widespread, applies to the temperature or the pressure large fluctuation the pipeline or the high temperature, the high pressure and the low temperature pipeline, also uses in transporting the expensive medium, the flammable explosive medium, the poisonous gas pipeline.

Disadvantage: with neck butt welding flange bulky, heavy weight, expensive, installation positioning is difficult. So it’s easier to bump in transit.

Detail information of carbon steel welding neck flange:

| standard | Sealing surface | Pressure/grade PN/MPa |

| HG20595 JB/T82-94 GH/T9115-2000 |

RF | 1.0~25.0 |

| MFM | 1.0~16.0 | |

| TG | 1.0~16.0 | |

| RJ | 6.3~25.0 | |

| FF | 1.0~1.6 |

![]()

The connection between the pipe flange and the pipe must meet the following requirements:

1 The center of the pipe and the flange should be on the same horizontal line.

2 The center of the pipe is perpendicular to the sealing surface of the flange at a 90 degree angle.

3 The position of the flange bolts on the pipe should be consistent.

What are the international common standards of pipe flanges?

The common international standard for pipe flanges can be summed up as two different and not interchangeable pipe flanges: One is the European flange system represented by Germany, and the other is the American pipe flange system represented by the United States. Germany and the United States the two major systems of the nominal pressure of the pipe flange is basically different, cross but there are duplicates, two system of pipe flange connection size is completely different, can not match each other.welding flange include slip on flange and weld neck flange.

Different slip on flange and welding flange?

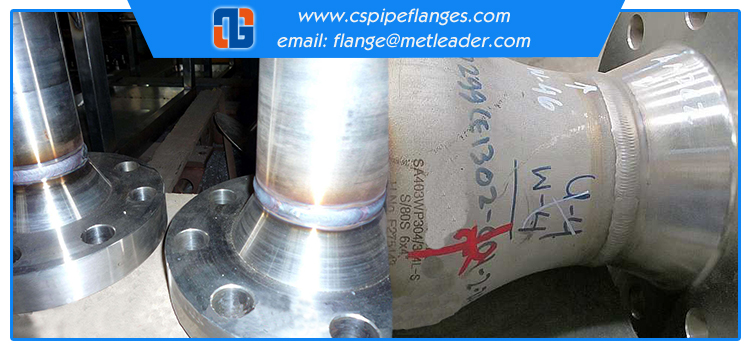

The welding neck flangee is the pipe diameter and wall thickness of the interface end as well as the pipe to be welded, which is welded as two tubes.

The slip on flange is a concave table machined with a slightly larger outside diameter than the pipe, which is welded inside.

Slip on flange and welding neck flange refers to the flange and pipe connection when the welding method, flat welding flange welding when only one side welding does not need to weld the pipe and flange connection of the inner mouth, butt welding flange welding installation needs flange double-sided welding. So the flat welding flange is generally used for low, medium pressure pipe, butt welding flange for medium and high pressure pipe connection, the flange of the welding is generally at least pn2.5mpa, using butt welding is to reduce stress concentration, the general butt welding Farrando for neck flange is also called high neck flange. Therefore, the installation of welding flange costs, labor costs and ancillary costs to high, because more than a process.

![]()

Another type pipe flange:

|

|

|

|

|

| carbon steel socket flange | 6 inch pn 16 stainless steel SO flange | 2 inch carbon steel blind flange | 6 inch stainless steel weld neck flange | carbon steel plate flange |

The different size welding neck flange:

2 inch carbon welding neck flange

6 inch stainless weld neck flange

ASME B16.5 carbon steel WN flange