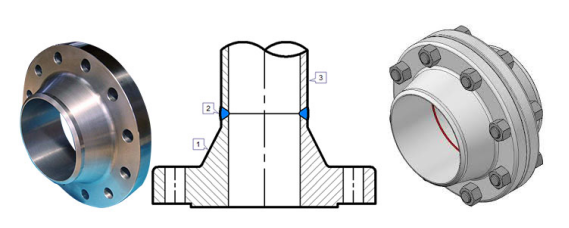

What is carbon steel pipe welding neck flange?

This is a kind of carbon steel flange with long neck. It can be widely used for connection between steel pipes or steel pipes and fittings of pipeline system. Welding neck flange has many kinds of dimensions, pressures and materials.

Some datas about carbon steel welding neck flange.

| For Carbon Steel Welding Neck Flange | |

| Manufacturing Standard: | ASME B16.5/16.47, DIN, JIS, GB, GOST etc. |

| Material Standard: | ASTM A105, DIN17200, CK22, SF34, Steel20 etc. |

| Size Range: | 1/2”, 1”, 11/4”, 11/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 18”, 20” to 48”. (DN15-DN1200) |

| Pressure: | CL150, CL300, CL600, CL900, CL1500, CL2500, PN6 to PN100, and 5K to 40K |

| Surface Coatings: | Black painting, anti-rust oil, epoxy coated, galvanized and yellow painting. |

There are five types of sealing faces for welding neck flange.

| Type: | RF (raised face) | FF (flat face) | FM (female and male) | TG (tongue and groove) | RJ (ring joint) |

| Application range: | Middle pressure | Low pressure | Middle & high pressure | Middle & high pressure | High pressure and temperature |

FF Type:

RF Type:

FM Type:

TG Type:

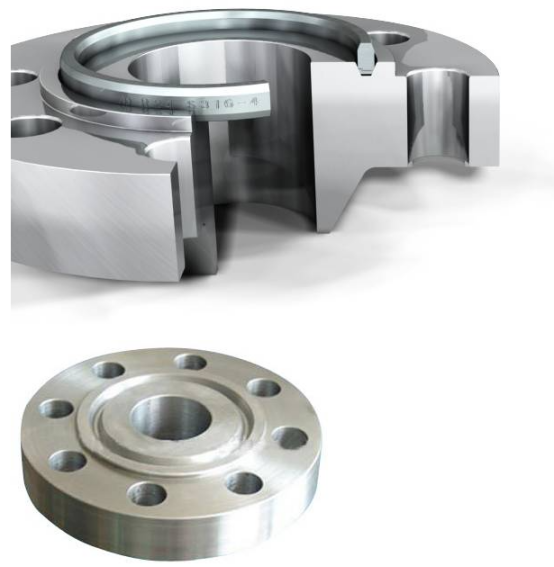

RJ Type:

How to guarantee good quality flanges?

First, production process of welding neck flange must be forged.

Second, to choose the raw materials produced by big steel factories and retesting them after receiving.

Third, do the good job in the production testing for each producing step.

Last, do the good job in the inspection for finished products.