Carbon steel pipe flange specifications

Flange is a disk-like part, in the boiler, pipeline engineering is the most common, flange is mainly used for pipe connection, which called carbon steel pipe flange. Carbon steel pipe flange specifications are as follow: slip on flange, plate flange, weld neck flange, threaded flange, socket flange, lap and joint flange.

In the need to connect the pipeline interface, the installation of a flange, low pressure pipe can use threaded flange, more than 4 kg the pressure of the use of welding flange. The two plates are sealed between the flanges and then fastened with bolts. Different pressure flanges have different thicknesses and different bolts. Pumps and valves, in connection with the pipeline, these equipment parts, also made of the corresponding flange shape, also known as flange connection. All the connected parts which are bolted and closed at the periphery of two planes are generally called “flanges”, such as the connection of the ventilation pipe, which can be called “Flange type parts”.

Carbon steel pipe flange specifications of types

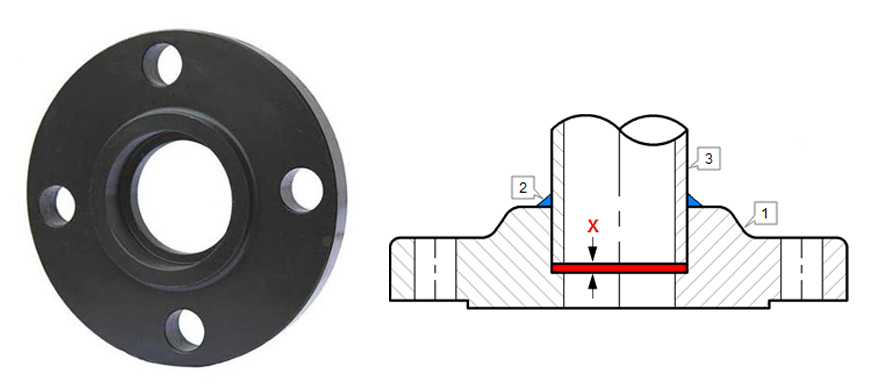

1.Slip on Flange/Plate Flange

The most commonly used one of the flat welded flanges. The flange and the fixed form of the pipe, is the flange sleeve at the end of the pipe, welding Falanrico and external mouth, so that the flange fixed, the applicable nominal pressure of not more than 2.5MPa.

Carbon steel pipe flange specifications of slip on flange

Advantages: Easy to draw, easy to manufacture, low cost and widely used.

Disadvantages: poor rigidity, so it must not be used for supply and demand, flammable, explosive and higher vacuum requirements of the chemical process piping system and high, extremely hazardous occasions.

2.Welding Neck Flange

Welding Neck flange strength, not easy to deformation, good sealing performance, there are many forms of sealing surface, the applicable pressure range is very wide.

Carbon steel pipe flange specifications of welding neck flange

Advantages: The connection is not easy to deform, the sealing effect is good, the application is widespread, applies to the temperature or the pressure large fluctuation the pipeline or the high temperature, the high pressure and the low temperature pipeline, also uses in transporting the expensive medium, the flammable explosive medium, the poisonous gas pipeline.

Disadvantages: with neck butt welding flange bulky, heavy weight, expensive, installation positioning is difficult, so in transit more easily bump.

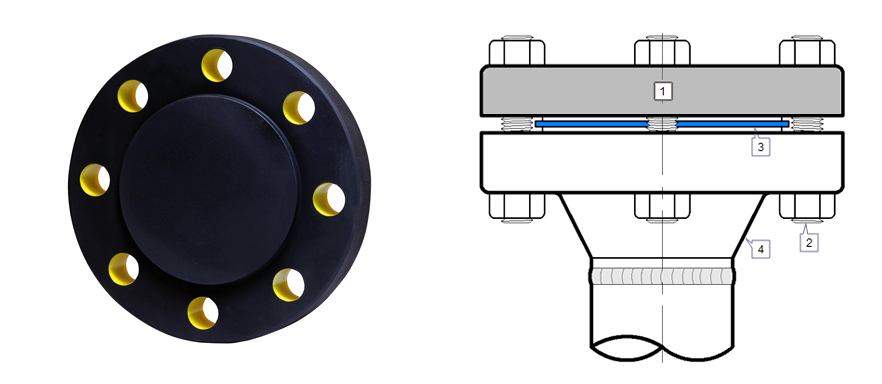

3.Blind Plate Flange

Blind flange is also called flange cover, is the middle without holes in the flange, for sealing the pipe plug.The function is the same as the welded head and the wire buckle cap, except that the blind flange and the screw cap can be unloaded at any time, and the welded head is not.

4. Threaded Flange

Flanges with threaded flanges with pipe ends are of high pressure and low pressure.

Carbon steel pipe flange specifications of threaded flange

Advantages: It is a peaceful welding flange or butt welding flange, threaded flange with installation, maintenance convenient features, can be used in some sites do not allow welded pipelines.Alloy steel Flange has enough strength, but not easy to weld, or welding performance is not good, can also choose threaded flange.

Disadvantage: It is recommended not to use threaded flanges to avoid leakage when the pipe temperature changes sharply or the temperature is above 260 ℃ below 45 ℃.

4.Socket Flange

The socket welding flange is a bolted flange connected to the other end of the pipe.

Carbon steel pipe flange specifications of socket flange

Application Range: Boiler pressure vessel, petroleum, chemical, shipbuilding, pharmacy, metallurgy, machinery, food and other industries.Used in pn≤10.0mpa,dn≤40 pipelines.

5.Lap and joint Flange

Lap and joint flange will be the same material with the pipe welding ring, directly welded in the pipe end, the use of solder ring as a sealing surface, its sealing surface has a smooth and tenon groove type.

Carbon steel pipe flange specifications of lap and joint flange

Function: The purpose of using the ring flange is to save the material, the structure is divided into two parts, pipe and pipe, one end of the weld ring.The flange uses low grade material, and the pipe part uses the same material as the pipe, achieves the material saving purpose.