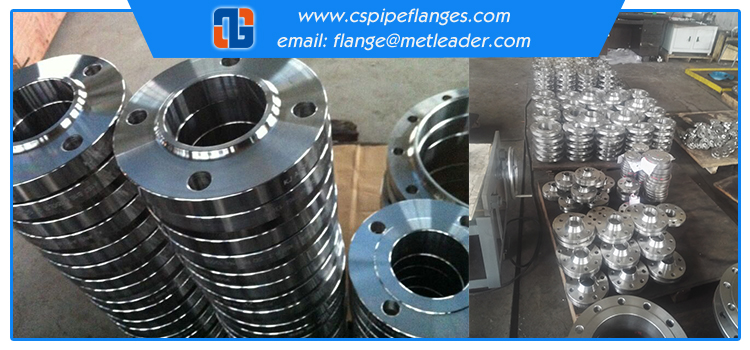

Carbon steel forged slip on flanges

carbon steel forged slip on flanges is commonly referred to as flat flange.The connection of slip on flanges to pipes is to insert the pipe into the proper position in the flange first, and then weld the flanges, such as the flat welding flanges, to the piping system with low pressure level, pressure fluctuation, vibration and shock. The advantage of flat welding flange is that the flat welding flange is easier to be welded when assembled.

Flat welding flange is commonly referred to as flat flange, also called welded flange. The connection between flat welding flange and pipe is to insert the pipe into the flange hole to the appropriate position before welding.

carbon steel forged slip on flanges is suitable for piping system with low pressure rating, pressure fluctuation, vibration and shock. carbon steel forged slip on flanges has been widely used because it is easy to align and cheap in welding and assembling.

Product specification DN10-DN2000

Commonly used standard Ministry of chemical industry HG/T20592-2009 national standard GB/T9119-2000 Mechanical Department JB/T81-94 ship logo GB/T2506-2005

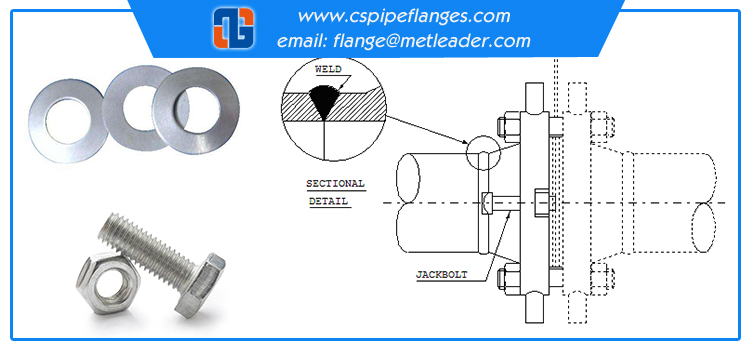

How to connection of slip on flange:

Flange connection is made up of a pair of flanges, a gasket and several bolts and nuts. The gasket is placed between the cover of two methods, and after tightening the nut, the surface of the cushion has a certain amount of deformation, and fills the dense cover with a concave and uneven place to make the connection tight. The flange connection is a detachable connection. According to the connected parts can be divided into container flange and pipe flange; according to the structural type, there are integral flange, looper flange and thread flange. Common flange has plain welding flange and butt welding flange. The rigidity of the flat welding flange is poor, it is suitable for the situation of pressure P less than 4MPa; the welding flange is also called the high neck flange, and the rigidity is larger. It is suitable for the situation where the pressure temperature is high. There are three types of flange sealing surface: plane type sealing surface, suitable for low pressure and non-toxic media; concave and convex sealing surface is suitable for high pressure occasions; tenon and tenon sealing surface is suitable for flammable, explosive, toxic media and high pressure occasions.

![]()