What are the limitations of slip on flanges?

What is the pressure rating of a 150 slip-on flange?

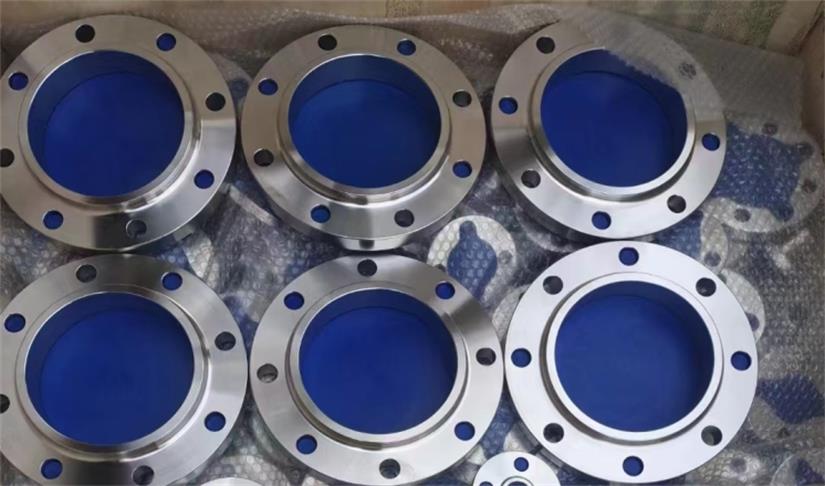

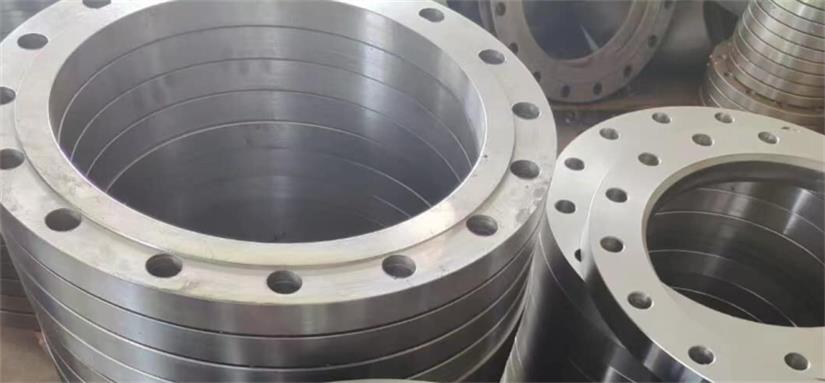

Slip-on flanges are a type of pipe flange that is slipped over the end of a pipe and then welded in place. They are designed to slide over the pipe and have a small inside diameter, which allows them to fit over the pipe’s outer diameter.

What are the limitations of slip on flanges?

Slip-on flanges typically have lower pressure ratings compared to other types of flanges, such as weld neck flanges. This makes them less suitable for applications that require handling high-pressure fluids or gases.

Due to their design and the method of attachment, slip-on flanges may be more susceptible to creep and stress rupture under high-temperature and high-pressure conditions. This can limit their use in applications with demanding thermal or pressure requirements.

Slip-on flanges may have reduced structural integrity for larger pipes and higher loads. In these cases, weld neck flanges or other types designed for greater load-bearing capacity may be more appropriate.

It’s crucial to carefully assess the specific requirements of an application and consider these limitations when choosing flange types. In some scenarios, alternative flange designs may better meet the demands of the system in terms of pressure, temperature, and material compatibility.

What is the pressure rating of a 150 slip-on flange?

Designed for maximum pressure of 150 psi at temperatures ranging from -20°F to 100°F (-29°C to 38°C).

It’s important to note that the pressure rating is influenced not only by the class but also by the material of construction. Different materials, such as carbon steel, stainless steel, or other alloys, may have varying pressure-temperature ratings even within the same class.

Before selecting or using a slip-on flange, it’s crucial to verify the specific material and associated pressure-temperature rating to ensure it meets the requirements of the intended application. Additionally, adherence to relevant industry standards and regulations is essential for the safe and effective use of flanges in different piping systems.